Gas flexibility: The occurring BOG can either be used as fuel gas or it can be re-liquefied and returned to the tanks after the optional, parallel arranged reliquefaction plant.

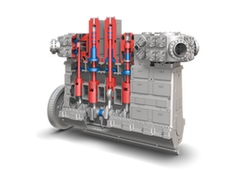

Operational flexibility: The Laby®/Laby®-GI is insensitive to parameters such as suction temperature, gas composition and suction pressure and can be operated with outstanding efficiency, over a wide range of process duty parameters.

The Laby® compressor vibrations are minimized to prevent damaging the LNG tank systems. In addition, the Laby®-GI is fully balanced and vibration free.

Between the compressor stages, gas side streams to feed e.g. re-liquefaction, auxiliary engines or other processes, allow multi-purpose compression and eliminate individual equipment per process.

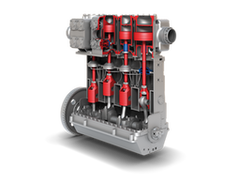

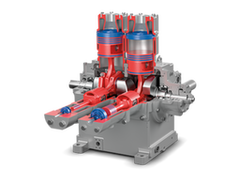

Burckhardt Compression's Marine Compressor solutions are used to deliver up to 350 bara injection pressure to dual-fuel engines that operate in the Diesel-cycle and up to 20 bara within the Otto-cycle.

The compact Marine Compressor solutions offer the chance to install redundant compressors even if space is very limited.

Specific design for easy service allows crew to do the service on board.

Burckhardt Compression's Marine Compressor solutions are used to deliver up to 350 bara injection pressure to dual-fuel engines that operate in the Diesel-cycle and up to 20 bara within the Otto-cycle.

The compact Marine Compressor solutions offer the chance to install redundant compressors even if space is very limited.

Specific design for easy service allows crew to do the service on board.

With regard to the efforts made to reduce the global carbon footprint, cruise ship passengers are increasingly requesting low-emission cruise voyages. LNG is the preferred alternative fuel for new cruise ships. Occurring boil-off gas (BOG) must be managed to protect the structural integrity of the onboard gas tanks.

Burckhardt Compression offers a variety of compressor solutions for BOG handling that have been specifically designed for marine applications. Our oil-free Laby® Compressors can compress the BOG for injection into auxiliary gen-sets.

Reciprocating compressor solutions offer the best in class gas control due to the insensitivity of this technology to dynamic suction/discharge pressure, mass flow changes and gas composition.

The Laby® Compressor solution for BOG handling on FSRUs on top of that maximizes the operational flexibility due to the use of temperature insensitive and contactless, oil-free labyrinth sealed pistons and piston rods, eliminating the need for gas pre-warming or compressor pre-cooling.

Compressor vibrations are minimized to prevent damaging the LNG tank systems.

Between the compressor stages, gas side streams to feed e.g. re-liquefaction, auxiliary engines or other processes allow multi-purpose compression and eliminate individual compressor equipment per process.

The Laby® Compressor solution is designed gas tight to eliminate gas loss to the flare and N2 purging.