MT COOLANT CHECK (Patent Pending): Innovative, Non-Chemical and Environmentally Friendly Engine Coolant Quality Assessment

Regular testing of engine cooling water on board a vessel by the crew is essential in order to protect the cooling water system from corrosion and to enable effective cooling of the engine.

During the engine operation, the anti-corrosive performance of the cooling water in use, and respectively its quality, is usually gradually deteriorating or in some cases sudden and rapid changes can happen. Due to poor quality of the cooling water, corrosion may occur which can lead to unexpected operating problems, damages and major engine failures, when left untreated.

Until now, routine on-board engine coolant analysis was conducted with the help of portable test kits which all use chemicals, predominantly classified as hazardous products for the environment. Utilising different chemicals, complex physical and/or chemical analyses of individual parameters (chlorides, nitrite additives, sulphates, pH etc.) are performed in order to quantitively determine (in “ppm” or “mg/l”) whether the anti-corrosion effect of the coolant in use is still sufficient. When individual parameters are out of specified limits, usually addition of additives or coolant change are the measures to follow. Martechnic’s own test kits COOLANT AND LUBE OIL and MT COOLING WATER CHECK have been part of this conventional approach.

Technological Advancement in Engine Coolant Testing

With the focus on innovative solutions and improvement of its existing products for cooling water on-board testing, Martechnic has developed and designed an innovative, patent pending test device MT COOLANT CHECK. The state-of-the-art testing equipment offers chemical-free, environmentally friendly and sustainable engine coolant assessment as a part of proactive predictive maintenance practices.

The test device MT COOLANT CHECK simplifies the testing process by analysing water-based coolants with just one single measurement of a small coolant sample of 30 ml by means of the electrotechnical apparatus, with constant (corrosion resistant) and working/ changeable (corrosion-prone) electrodes in a simulated engine cooling system. No chemicals are required at all.

Both electrodes are subjected to corrosion stress. The performance of the engine coolant is characterized in relation to its existing level of corrosion protection on the metals used in the cooling system. All the evaluation is carried out fully automatically delivering results in just 15 minutes. The remaining corrosion protection of the engine coolant in use is determined with a new unit of measurement: Lagner (lag).

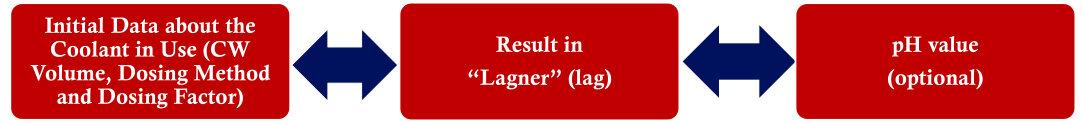

If the anti-corrosive effect of the engine coolant in use is insufficient, the dosing rate of the chemical additive to be added is automatically calculated, by entering the following available technical data provided in the manufacturer's coolant specifications:

- CW (cooling water) volume in m3

- Dosing method: liquid or powder

- Dosing factor: l/m3 or kg/m3

The MT COOLANT CHECK can also automatically measure and directly display the pH value of the coolant sample through the integration of a separate optional pH electrode into the sensing head of the test device. The pH electrode will then replace the use of disposable pH test strips.

On the basis of the data received, the maintenance crew on-board a vessel receives a clear recommendation to further actions if required.

By offering precise and timely maintenance recommendations, the test device helps to avoid unnecessary coolant changes and wastage. The MT COOLANT CHECK can be used for testing different coolant formulations regardless of the coolant additive composition/ specific manufacturer.

Eco-Friendly and Sustainable Engine Coolant Testing

The MT COOLANT CHECK of Martechnic offers environmentally-friendly and resource-efficient measurement method employing steel and stainless steel, long-lasting test electrodes instead of hazardous chemicals.

The electrodes are easily recyclable with no shelf-life limitations and can be disposed as a regular scrap metal on each vessel without any binding restrictions of country specific environmental regulations. Thereby, no chemical waste is generated. The use of electrodes contributes in general to waste reduction, minimizing environmental risks, especially to marine ecosystems, thereby marking a significant stride towards sustainable proactive predictive maintenance in the maritime industry.

Implementing chemical-free testing of the engine coolant with the MT COOLANT CHECK into regular on-board condition monitoring programs allows ship operators to reduce their overall ecological CO2 footprint saving costs and protecting the environment.

Contact details

Martechnic GmbH

Adlerhorst 4,

D-22459 Hamburg, Germany

Tel.: +49 (040) 853 128 0

Fax: +49 (040) 853 128 16