Company Insight

Sponsored by DHI

DHI tests of ballast water management systems – best service to manufacturers is what matters

Twelve of the 22 U.S. Coast Guard type approvals granted to ballast water management systems by October 7, 2019, were based on testing conducted by DHI. DHI continuously improves procedures to deliver efficient testing made possible by an experienced international team and the flexible land-based test facility in Denmark.

DHI’s test facility in Hundested, Denmark, is located with easy access to high quality source water for type approval testing and can simultaneously accommodate 5 to 6 ballast water management systems.

DHI Ballast Water and Laboratories provides independent biological performance evaluation of ballast water management systems (BWMS) according to the requirements by the International Maritime Organization (IMO) and the United States Coast Guard. Type approval of BWMS is granted by the IMO flag state or the U.S. Coast Guard after the successful completion of biological efficacy tests conducted by DHI and other test facilities. The U.S. Coast Guard regulation of ballast water discharged to U.S. waters entered into force already in 2012, and BWMS manufacturers targeting globally operating vessels need to have their systems type approved by the U.S. authorities. The U.S. Coast Guard had granted 22 type approvals of BWMS by October 7, 2019, and applications representing 10 BWMS are currently under review.

Twelve of the U.S. Coast Guard type approvals (October 7, 2019) were based on testing conducted by DHI. The manufacturers of these systems were Alfa Laval (Sweden; two type approvals), TeamTec OceanSaver (Norway), Sunrui (China), BIO-UV (France), Wärtsilä Water Systems Ltd. (UK; two type approvals), Hyundai Heavy Industries Co. (Republic of Korea), Headway Technology Co., Ltd. (China), Panasia (Republic of Korea), DESMI Ocean Guard (Denmark), and COSCO Shipbuilding Industry Co., Ltd. (China). The purpose of the land-based test is to evaluate the biological efficacy of the BWMS under challenging conditions in a large-scale controlled experiment. The land-based test requires that the test facility staff are trained and capable of running the BWMS through the typical series of at least 15 test cycles. The technical dialogue between the manufacturer and DHI prior to the planning of the test is the first important step in a successful biological performance evaluation. “Our team includes people from countries in Asia and Europe – this gives us the benefits of different languages and cultural diversity that are valuable for the communication with our customers”, says Rémi Maguet, Project Manager at DHI.

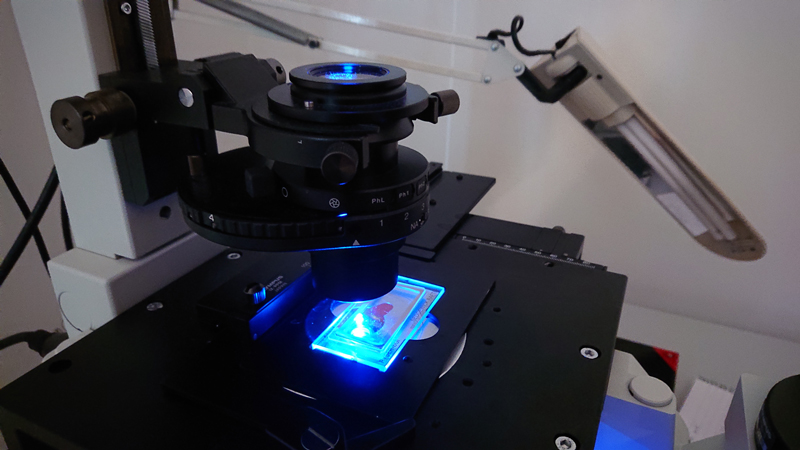

DHI Ballast Water and Laboratories. A view into DHI’s environmental laboratory. Microscopy counting and evaluation of treated discharge water

Title

DHI has agreements with three independent laboratories that are recognized by U.S. Coast Guard for the evaluation of BWMS type approval tests: DNV GL, Lloyd’s Register and Korean Register. The collaboration with DNV GL and Lloyd’s Register has developed through many projects, while DHI has not yet conducted type approval testing together with Korean Register. Several manufacturers from China, Japan and Korea, however, have been testing their BWMS at DHI’s test facility in Denmark, and it is the ambition of DHI to continue and expand the dialogue with manufacturers in Asia.

The experienced team and flexible work processes are the reasons for the efficient BWMS type approval testing at DHI. The land-based test facility can accommodate up to six BWMS, and an extra 1,000 cubic meter source tank was established in 2019. The extra source tank increases the flexibility of DHI’s test facility even further, as Gitte I. Petersen, Head of Department, explains: “Many of our customers want to expand the testing programme to include an alternative filter or to verify the biological treatment efficacy, when the ballast water is discharged with the shortest possible holding time in the ballast water tanks – we have now even better possibilities to meet the needs of the manufacturers.” The commercial interest is that the treated ballast water complies with the regulations and preferably can be discharged directly after treatment by the BWMS – this means that the requirements to live organisms at discharge shall be fulfilled without the extra ‘help’ provided by the die-off during the storage in the ballast water tanks. The related BWMS type approval test concept is called ‘performance testing with reduced holding time’. DHI is ready to perform the testing to provide the required documentation to support the claim that the BWMS can treat ballast water with reduced holding time.

Commissioning testing of BWMS directly after the installation on board the ship is currently being requested by ship-owners to comply with IMO guidance and requirements by Singapore applicable for ships under Singapore flag. DHI performs commissioning tests of BWMS, and the DHI team in Singapore can easily reach ship-yards in China, where most of the commissioning testing will take place. The commissioning test shall verify that the BWMS treats the ballast water in accordance with the IMO D-2 standard. Meeting this requirement implies that representative sampling of treated ballast water and reliable, validated analyses of the concentrations of live organisms. DHI makes use of mobile laboratories and is well-prepared to perform commissioning tests of newly installed BWMS.

Seagull view of DHI’s test facility - with seven test tanks and culture ponds (lower left corner).