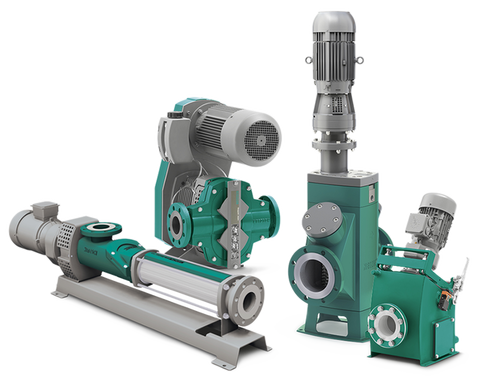

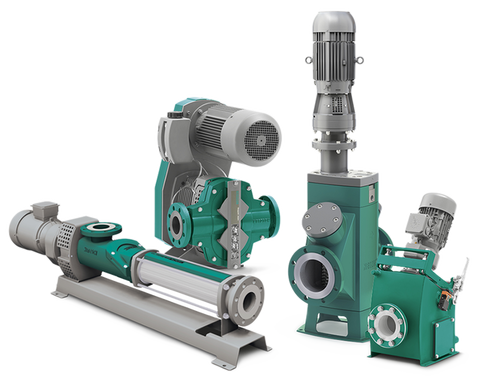

To cover the full range of requirements for maritime use, NETZSCH Pumps & Systems has developed different product series, which can be universally deployed as transfer and booster aggregates on ships and on wharves, as well as on offshore platforms. The NEMO® progressing cavity, TORNADO® rotary lobe, NOTOS® screw pumps and NETZSCH macerators cover a really wide range of application areas from fuel or sludge transport, through loading and unloading, to stripping.

Hover on the text around to read more

Container ships

Container ships use the NEMO® pump for used oil, oil sludge, oily water and wastewater, the NOTOS® multi screw pump as a hydraulic and windlass pump or for lubricant oil and fuel.

Container ships use the NEMO® pump for used oil, oil sludge, oily water and wastewater, the NOTOS® multi screw pump as a hydraulic and windlass pump or for lubricant oil and fuel.

Oil platform supply ships

On oil platform supply ships, the NEMO® pump is predominantly used to convey sludge and drilling chemicals and the NOTOS® multi screw pump for lubricant oil, fuel and cylinder oil, as well as for stripping and heavy oil separation. In addition, the N.Mac® macerator is used for wastewater.

On oil platform supply ships, the NEMO® pump is predominantly used to convey sludge and drilling chemicals and the NOTOS® multi screw pump for lubricant oil, fuel and cylinder oil, as well as for stripping and heavy oil separation. In addition, the N.Mac® macerator is used for wastewater.

Oil tankers

On oil tankers, the NEMO® pump is used for residual oil, oil sludge and oily water, the NOTOS® multi screw pump to circulate lubricant oil and the TORNADO® rotary lobe pump to load and unload crude oil.

On oil tankers, the NEMO® pump is used for residual oil, oil sludge and oily water, the NOTOS® multi screw pump to circulate lubricant oil and the TORNADO® rotary lobe pump to load and unload crude oil.

Passenger Ships

On passenger ships, the NEMO® pump is used for wastewater, the NOTOS® multi screw pump for lubricant oil and fuel in the engine room and the N.Mac® macerator for grinding and separating large, hard objects in wastewater.

On passenger ships, the NEMO® pump is used for wastewater, the NOTOS® multi screw pump for lubricant oil and fuel in the engine room and the N.Mac® macerator for grinding and separating large, hard objects in wastewater.

Wharves

On wharves, the media conveyed by the NEMO® pump include highly viscous materials and chemicals. It is also used for stripping tanks and cleaning pipelines, while the TORNADO® pump is responsible for loading and unloading oil and recirculating oil residues.

On wharves, the media conveyed by the NEMO® pump include highly viscous materials and chemicals. It is also used for stripping tanks and cleaning pipelines, while the TORNADO® pump is responsible for loading and unloading oil and recirculating oil residues.

Production & storage units

On production and storage units, the NEMO® pump conveys industrial sludge, wastewater and oil-gas mixtures, the TORNADO® rotary lobe pump is used for crude oil and used industrial oil and the NOTOS® multi screw pump for lubricant oil and fuel or for the hydraulic system.

On production and storage units, the NEMO® pump conveys industrial sludge, wastewater and oil-gas mixtures, the TORNADO® rotary lobe pump is used for crude oil and used industrial oil and the NOTOS® multi screw pump for lubricant oil and fuel or for the hydraulic system.

Offshore platforms

Offshore platforms use the NEMO® pump for industrial sludge and oil-gas multiphase mixed chemicals, the NOTOS® multi screw pump for lubricant oil and fuel and the TORNADO® rotary lobe pump for used industrial oil, drill cuttings and drilling sludge.

Offshore platforms use the NEMO® pump for industrial sludge and oil-gas multiphase mixed chemicals, the NOTOS® multi screw pump for lubricant oil and fuel and the TORNADO® rotary lobe pump for used industrial oil, drill cuttings and drilling sludge.

Bulk carriers

In addition to the transfer of used oil, oily water and wastewater, the NEMO® pump is also used on bulk carriers for stripping, the NOTOS® multi screw pump for hydraulic and lubricant oil and for chemicals as well. The TORNADO® rotary lobe pump can function as a loading and unloading pump for crude oil.

In addition to the transfer of used oil, oily water and wastewater, the NEMO® pump is also used on bulk carriers for stripping, the NOTOS® multi screw pump for hydraulic and lubricant oil and for chemicals as well. The TORNADO® rotary lobe pump can function as a loading and unloading pump for crude oil.

To cover the full range of requirements for maritime use, NETZSCH Pumps & Systems has developed different product series, which can be universally deployed as transfer and booster aggregates on ships and on wharves, as well as on offshore platforms. The NEMO® progressing cavity, TORNADO® rotary lobe, NOTOS® screw pumps and NETZSCH macerators cover a really wide range of application areas from fuel or sludge transport, through loading and unloading, to stripping.

Passenger ships

On passenger ships, the NEMO® pump is used for wastewater, the NOTOS® multi screw pump for lubricant oil and fuel in the engine room and the N.Mac® macerator for grinding and separating large, hard objects in wastewater.

Oil tankers

On oil tankers, the NEMO® pump is used for residual oil, oil sludge and oily water, the NOTOS® multi screw pump to circulate lubricant oil and the TORNADO® rotary lobe pump to load and unload crude oil.

Oil platform supply ships

On oil platform supply ships, the NEMO® pump is predominantly used to convey sludge and drilling chemicals and the NOTOS® multi screw pump for lubricant oil, fuel and cylinder oil, as well as for stripping and heavy oil separation. In addition, the N.Mac® macerator is used for wastewater.

Container ships

Container ships use the NEMO® pump for used oil, oil sludge, oily water and wastewater, the NOTOS® multi screw pump as a hydraulic and windlass pump or for lubricant oil and fuel.

Bulk carriers

In addition to the transfer of used oil, oily water and wastewater, the NEMO® pump is also used on bulk carriers for stripping, the NOTOS® multi screw pump for hydraulic and lubricant oil and for chemicals as well. The TORNADO® rotary lobe pump can function as a loading and unloading pump for crude oil.

Offshore platforms

Offshore platforms use the NEMO® pump for industrial sludge and oil-gas multiphase mixed chemicals, the NOTOS® multi screw pump for lubricant oil and fuel and the TORNADO® rotary lobe pump for used industrial oil, drill cuttings and drilling sludge.

Production and storage units

On production and storage units, the NEMO® pump conveys industrial sludge, wastewater and oil-gas mixtures, the TORNADO® rotary lobe pump is used for crude oil and used industrial oil and the NOTOS® multi screw pump for lubricant oil and fuel or for the hydraulic system.

Wharves

On wharves, the media conveyed by the NEMO® pump include highly viscous materials and chemicals. It is also used for stripping tanks and cleaning pipelines, while the TORNADO® pump is responsible for loading and unloading oil and recirculating oil residues.

Universally deployable displacement pumps ensure reliable, smooth conveyance of a very wide range of media

To cover the full range of requirements for maritime use, NETZSCH Pumps & Systems has developed different product series, which can be universally deployed as transfer and booster aggregates on ships and wharves, as well as on offshore platforms. The NEMO® progressing cavity, TORNADO® rotary lobe, NOTOS® multi screw pumps together with NETZSCH macerators cover a really wide range of application areas – from fuel to sludge transport, through loading and unloading, even to stripping. Especially the TORNADO® rotary lobe and the NOTOS® multi screw pumps are ideal for the maritime sector because of their compact design whilst ensuring high flow rates.

NEMO® progressing cavity pumps can cope with liquid media which contain solids, which means they are for instance frequently used on passenger and container ships to convey wastewater. The main advantage of the Nemo® progressing cavity pumps and it’s technology is the fact that the consistency, and especially the viscosity, of the medium are insignificant in terms of the product flow. This makes the Nemo® progressing cavity pumps applicable in a very broad range.

TORNADO® T2 pumps in particular are specifically suitable for the demands of use on the high seas: They are self-priming, valveless positive displacement pumps which can be optimally customized to meet the applications on board. In addition to their compact design, the minimum expenditure on spare part stock and the ease of maintenance is their major advantage. Long service or repair work are a thing of the past because of the special design with a large flange-to-flange cover plate and quick-fit non media-wetted taper locks of the shafts. It offers the possibility to exchange the rotors or other spare parts quickly without dismantling the pump from the pipework. The aggregate has an oil-free synchronised gear with belt drive. Time-consuming lubricant changes and the risk of environmentally hazardous leakages are not a problem anymore. The TORNADO® rotary lobe pumps are suitable for oil sludge or wastewater and many other solid loaden media.

The NOTOS® multi screw pumps excel in generating high pressures of up to 80 bar even in tight spaces and can cope with liquid temperatures of up to 300°C. A series of design innovations, in line with the principle of High Efficiency Unique Design (HEUD), involving the spindle profile and the pump chamber, make them particularly efficient. The three model series 2 NS, 3 NS and 4 NS allow flow rates maxima from 200 m³/h (2 NS) to a maximum of up to 1.500 m³/h (4 NS). The NOTOS® pumps are ideal for transporting lubricant oil, fuel and chemicals.

Last but not least all of our pumps can also be supplemented by high-performance macerators for the grinding and separation of larger, harder objects, primarily when conveying wastewater.

Contact Information

NETZSCH Pumpen & Systeme GmbH

Business Field Environment & Energy

Geretsrieder Strasse 1

84478 Waldkraiburg

Germany

Phone: +49 8638 63-1010

Fax: +49 8638 63-2333

Phone: +49 8638 63-1010

Fax: +49 8638 63-2333

Email: info.nps@netzsch.com

Website: www.pumps.netzsch.com