Interview

"It makes the crew happy" – Agwa CEO on growing food onboard vessels

Peter Nilson speaks to Agwa CEO Oren Saar about the company's growth in the maritime sector and how growing produce onboard vessels can be beneficial to everyone.

Oren Saar, Agwa CEO

Keeping crew fed at sea is a vital task, and the quality of food can have a huge impact on not just crew welfare and happiness, but also on a voyage's carbon footprint and budget. US-headquartered agri-tech startup Agwa is looking to revolutionise how seafarers are fed onboard, with its modular, autonomous devices that allow for greens and herbs to be grown onboard during a voyage.

Oren Saar, Agwa CEO, has a background in tech, having studied electrical and computer engineering at Ben-Gurion University in Israel, as well as gaining an MBA from MIT. After stints at Google and Boston Consulting Group, he founded his first company, WoodSpoon – an on-demand food ordering and delivery marketplace.

So with a background in tech, food, and as a co-founder of a startup, it's no surprise that a year and a half ago he joined Agwa, which was originally founded in 2020 by the company's current COO Alon Wallach and CTO Niv Stolarski.

Saar spoke to Ship Technology Global about how the company discovered a new niche for this micro-agronomy technology, the use cases already in place on vessels, and how growing produce onboard can lead to healthier and happier crew.

Peter Nilson: What's the story behind Agwa? How did the company start?

Oren Saar: I'll tell you what I know, the story that I was sold on when I decided to join. So, there was an idea that Alon Wallach and Niv Stolarski had. Alon is an agronomist in his background. He lived in Berkeley at the time, and he saw that a lot of people were trying to grow vegetables and having difficulties growing vegetables in their homes. And as an agronomist, he looked at it and said: "They are doing a lot of things completely wrong. There's just no chance they will be able to grow those vegetables."

The idea was to see how we could help them do it. This is where Agwa came from. The idea was, let's create this device that can grow vegetables for you. You don't need to do anything. You just need to connect it to WiFi, connect it to water, and you put capsules in, like you put capsules in an espresso machine, and the device does the magic itself.

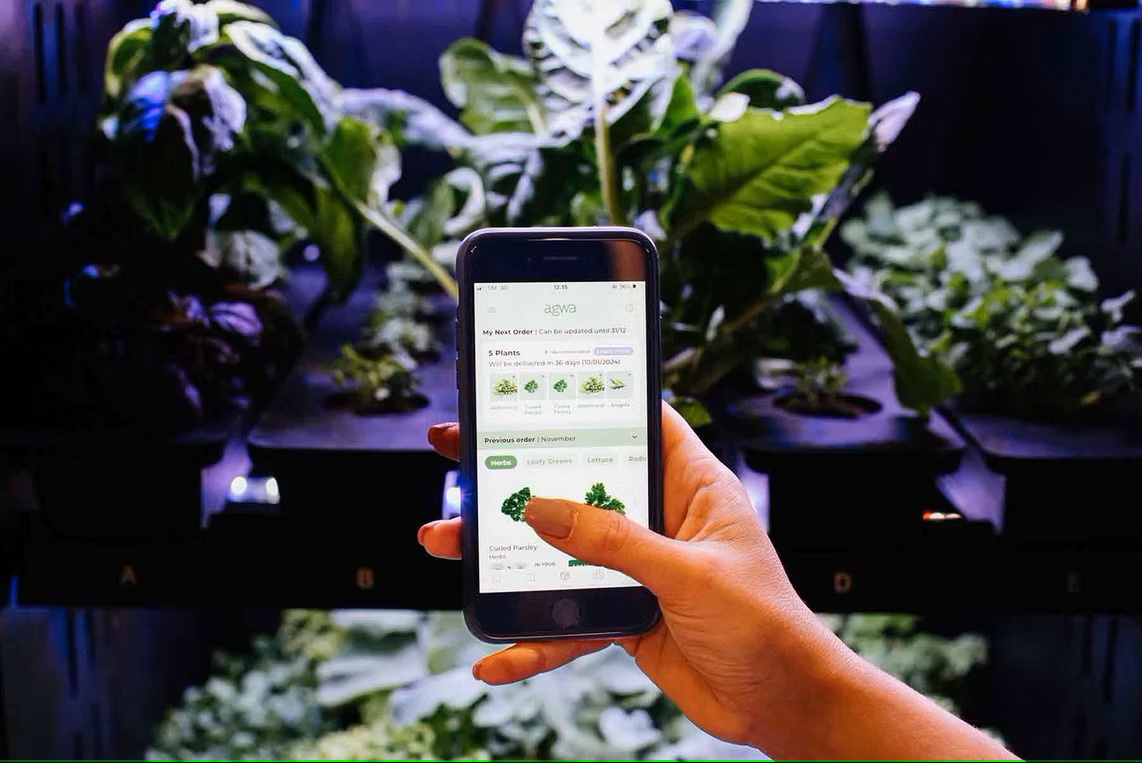

You have a mobile app that shows you the status of each plant, when you need to harvest, when you need to plant, and when it's going to be ready. The device gives it the exact amount of light it needs, the exact amount of fertiliser it needs, and waters it when it needs water. And this is the technology, which was created to take all this agronomy knowledge, put it on an AI machine, and tell the AI: "hey, take this, take the images that we give you from the device, and make sure you grow the vegetables in the best way possible."

Agwa actually started in the B2C market, with a few hundred households, a few hundred devices that were sold back in 2022, and the business model is very similar to what we have in the maritime space. You buy the device and then you pay a subscription on an annual basis. About 95% of people who bought it in 2022 are still actively using it. I have one in my house, it's life changing!

Peter Nilson: So how did the decision to move into the maritime sector come about?

Oren Saar: As someone who has sold his company [Woodspoon] in the B2C space, I'll tell you that the B2C is very, very challenging, and there needs to be a lot of conviction to grow in this space. So when I joined the company, we started to look for other verticals that we can have, what I call, a better product market fit. Not that we don't have it in the residential space, it's just that it's more challenging [in B2C]. There are more challenges in the consumer space than in the maritime space. We figured out that, you know, at home you have options. I can give you the device, but you can also go to the supermarket and buy decent vegetables. The device has a lot of benefits, but still, it's a hard sale.

What we did internally, we did a two by two matrix, to understand vertical farming and hydroponic farming. What verticals can it work best in? And we ended up doing like a two by two matrix, saying one vertical is remote location versus local. Local can be your house, a restaurant, a hospital, anything that can have access to vegetables; and remote is anything that does not have access to vegetables. It can be vessels, or coal mines in Alaska, or bunkers in Poland, or offshore oil rigs. Anything that does not have access - that's vertical number one.

Then the second axis, is basically if you have a large amount of people or a small amount of people. In the maritime space, if we go to cruise ships that have 10,000 people, I will probably need to put a million devices onboard in order to support those people. It does not make sense. So, you take those four boxes, and we ended up saying, okay, so we want to tackle remote locations with a small amount of people. Now start putting everything that is in this bucket. This is our go-to-market strategy. This is where we go in. And the maritime industry, in certain cases, ticked all the boxes.

An Agwa system growing leafy greens onboard a vessel. Credit: Agwa

In vessels in the maritime space, you now have, say 22 to 25 people in the middle of the Pacific Ocean, who literally don't have any access to fresh food.

And this is a different ballgame, and this is what we did. We figured out verticals where we have a clear advantage and a clear product market fit. This is how we ended up in the maritime space about a year and a half ago.

The first company we started working with was Eastern Pacific Shipping. Idan Ofer is the owner, and really he's a role model in the space. He made a decision. He said, I want to put [an Agwa system] on all of my vessels. I want to make sure my crew members have fresh vegetables when they go out to sea. And from there, it's kind of kept going, rolling on and on. And we now have systems onboard Capital Shipping vessels. We are also onboard CoolCo vessels, as well as some other pilots with other companies.

I think the industry received it very well. I have to say that everybody understands the need, everyone understands the benefits that we provide. And it's a very easy conversation to have, because if you offer something to someone that is at the same price as what they are already paying, then it's an easy sale. And that's the kind of conversation we're having with all of those companies.

Peter Nilson: What's your pitch when you speak to those companies? How do you convince them to adopt the new tech?

Oren Saar: So, what we quickly realised is that first of all, all those companies want to provide fresh vegetables to their crew members. They have a list of vegetables that they are providing, and what they'll do every time the vessel is in the harbor, they have an agent who buys those vegetables and onboards them.

Everything that is in the category of leafy green, like fresh vegetables, has a shelf life of 10 to 14 days. So whatever you don't consume in the first 14 days is thrown out. You will not be able to use it. If you have a voyage that is more than 14 days, then by definition, you understand that you're only going to have fresh vegetables for roughly speaking, the first two weeks. How those companies price their food operations is that they assume that they spend about $0.5 per day per crew member for those types of vegetables.

These are the types of vegetables Agwa can provide. When we show them what we can do, we basically tell them you will spend the same amount of money, but instead of getting the vegetables for the first 10 to 14 days, You will spend exactly the same amount of money, but you have those vegetables fresh all the time, 100% of the time. We will be able to feed your crew members with those types of vegetables. This is the first selling point.

It's the same money. It's easy to use. It saves you carbon footprint, and it just makes you happy.

The second selling point is that it's very easy to maintain. One of the things that we've heard from a few maritime companies is that they tried hydroponic solutions on vessels, but they quickly realised that the system needs to be maintained and somebody needs to take care of it 24/7. They need to water it. They need to put the fertilisers in. They need to measure it. They need to do a lot.

The clear benefit of Agwa is that you do not need to do anything. Our system, our AI agronomist, does everything for you. You go to the tablet. It tells you when to harvest, and you harvest. That's it. You put the capsules in. You take it out. You don't need to do anything.

So that was, you know, a clear second benefit for them. Number three is ESG. We reduce the carbon footprint from the supply chain a lot. We save a lot of water. It's healthier, more nutritious. We've made a dashboard on the app that shows users how many kilos of produce they are growing on each vessel and what the reduction in their carbon footprint is. Ship operators are now being measured on those ESG metrics. Agwa is a small but additional part of this reduction.

I think the fourth selling point – and I think I always say it as number four but I think it can also be 'number zero' – Crew welfare. The fact that they see this nice device with those green vegetables on board when everything else can be so grey. And this is big. Yeah, it makes them happy. We are running surveys, and in the surveys, we see that it's the best time of the crew's day. You know, when they harvest, or they say "Oh, we made these burgers in the middle of the ocean. We had those lettuces, and we did like this salad."

And they are happy, they send us pictures. So I think these are the top four clear benefits that we provide. It's the same money. It's easy to use. It saves you carbon footprint, and it just makes you happy. That's the clear benefit of this device.

Peter Nilson: How does an Agwa system work?

Oren Saar: From a size perspective, think of a medium wine fridge that has three shelves, each of which has space for 20 capsules. You're getting the capsules from us and they are pre-seeded. You just plant them wherever you want to plant them inside the device. The way the device works is that there is a camera on top of each of the three shelves. They're taking pictures twice a day – morning and evening. Those pictures go up to the cloud and are analysed by our AI algorithm. The AI algorithm understands the status of each plant.

So each plant undergoes analysis. Is this plant big enough? Does it need more nutrition? Does it lack light? Does it lack fertiliser? This is all done on the Cloud automatically. Once it's analysed, then the device is told what to do, for example, you need to give it more fertilisers or you need to give it more water. The device is updating itself to grow the vegetables in the best way possible. All this data goes on to the mobile app. So on the mobile app, you can see when it's going to be ready.

When I'm trying to explain the product, I say there are three layers of technology in the device. There's the image technology I described, but there's also sensor technology. We have about five different sensors in each device, monitoring things like EC levels, pH levels, water levels, humidity levels, all of which also go up to the cloud for analysis.

And the last layer is user behavior. So the AI looks at how you use it and starts to understand how it needs to grow vegetables in the best way possible to accommodate your needs. So let's say, for example, you are harvesting 20 lettuces a week. After three or four weeks, the AI will understand that the user is consuming 20 lettuces a week, so it needs to grow the vegetables in a way to ensure that every week there are 20 lettuces ready for harvest. So this is so it will do the things accordingly to make sure that you have what you need exactly when you need it. It will try to do its best to accommodate your needs as a user.

The Agwa app tracks the growth of produce, teeling users when they will be ready for harvest. Credit: Agwa

Peter Nilson: What kind of yield can you expect from each unit?

Oren Saar: Every unit is sufficient for about six to seven crew members. It really depends, like everything, on how much you are going to consume. What we calculated is a consumption of three big salad bowls, per person, per week. So not every day, but you know, three big ones per week. What each device can manufacture also depends on the type of vegetables that you will plant. We have more than 50 types of vegetables that can be grown, and we are always developing more.

We're always also listening to the customers. For example, we have an Indian crew, and they said: "Hey, we want spinach." And we say, Okay, so let's develop spinach. We have a Filipino crew that wanted Pak Choi, so we added Pak Choi to our line. So every crew is a little bit different and it depends on the vegetables you plant, because basil leaves are much bigger than parsley, but much smaller than Lalique Lettuce. So the grams can change. But on average, if you use the vegetable kits that we provide, each unit can grow about 750 grams to one kilo of leafy green per week.

So for each vessel of 22 to 24 people, we recommend installing between three or four devices. But it depends on what the company wants. We have companies that come to us and say that they only want to manufacture herbs. For this, we don't need a lot of devices. We just need two. And we have companies come to us and say, We want five because we want more than what you recommend. So it really depends on the company. It depends on the space they have, it depends on how much they want to spend.

Peter Nilson: What's on the horizon for Agwa?

Oren Saar: We're very excited about what we're doing now and also where we are heading. So we are doubling down on the maritime space, but we also have not forgotten the residential space. We are developing new devices as we speak for the residential space.

We are developing another device for the maritime space as well, so we can have two devices for the maritime sector. It's still under development, we're talking 2026 or 2027 in terms of release, but we are very excited about what we're doing and the future of those devices – and the future of Agwa in general.

We're very happy to see the consumption rate and what companies are saying when we talk to them. We're going to be in about four different exhibitions this year. So we're going out to Sea Asia 2025 to present there. We're going to another one here in the US that we're going to present at as well.

I mentioned earlier that we're piloting with some other companies in the maritime space. We are piloting with Maersk and we have big deals coming up with the Synergy Marine Group, with Anglo-Eastern, with V-Ships, with Fleet Management, and we also have Kumiai Navigation in Japan.

There are a lot of different companies that we're in pilots with, in active conversations and in active contract negotiations with. So, yeah, I think good things. Good things. We just need to keep going.